- ScalesNet History

- Benefits of ScalesNet

- Most Important Features

- The following modules are available

- Software Requirements

- Hardware Requirements

- Several Languages available

- Databasemodel

- Netzwork Connection Diagram

- Functions of ScalesMass

- Calibration of Customer Weights

- Calibration of Reference Weights

- Dissemination of mass scale

- Quick Comparison of Weights

- Manual Input of Weighing Data

- Calibration of Weighing Instrument

- Adjusting the Weighing Instrument

- Functions of ScalesDesk

- Customer Data

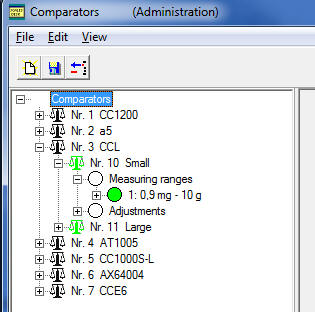

- Data of Balances / Comparators / Robots / Change-Loader / Prototyp-Comparator

- Reference Weights

- Employees

- Material of the Weights

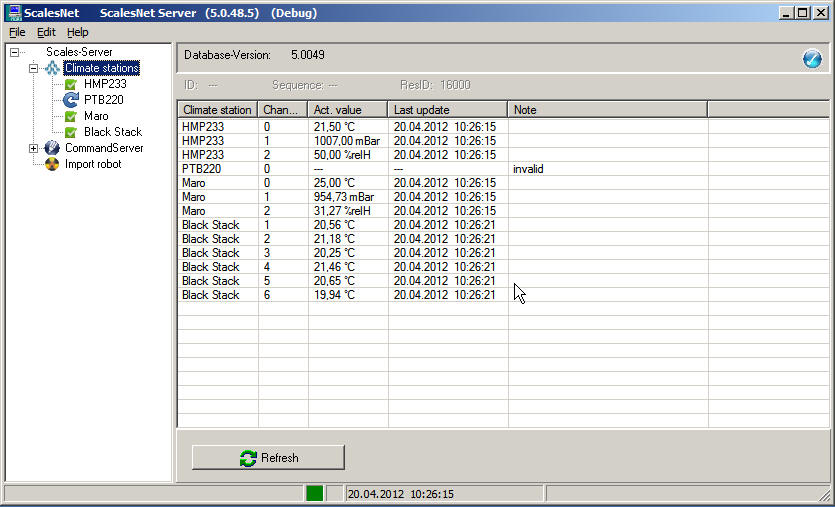

- Climate Stations

- Shapes of the Weights

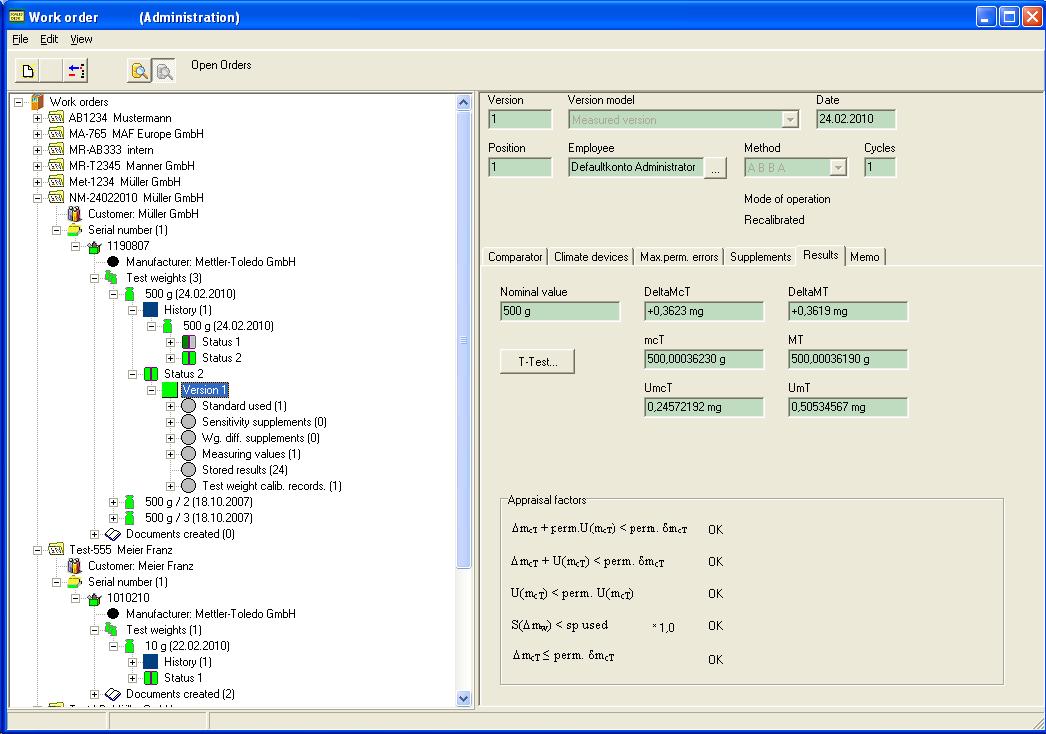

- Orders

- Preparing Reports and Records

- Trial Version of ScalesNet-M

- Demo-Sequenzen

ScalesNet History

Connecting Balances by Network - A leading Weight Calibration Software

The next development stage was defined by the requirements of weight manufacturers and was performed with the support of Mr. Haefner (Haefner Gewichte GmbH company). The new product was renamed to ScalesNet32 and put into production in 1999 at the Haefner Gewichte GmbH company.

With increasing international clients, the requirement arose to integrate a UNICODE SQL database into ScalesNet. A new ScalesNet version with integrated UNICODE database was released in 2004.

The latest overhaul and restructuring of ScalesNet was performed in 2010. ScalesNet was divided into modules. This ensures better customization options to adapt ScalesNet to customer demands. The current ScalesNet version has been renamed to ScalesNet-M (Modularity).

ScalesNet-M is undergoing continuous development, accommodating the requirements of the target markets and to enhance the product's capabilities. This allows adaptation to ever changing customer demands.

ScalesNet-M ensures that all calibrated weights can be traced to a defined National Standard and are in compliance with quality management requirements.

Benefits of ScalesNet

- Safe weight calibration

- Efficient measurement laboratory management

- Calculation and evaluating according to international guidelines such as OIML|ASTM

- The 3-1 measurement conforming to NIST SOP5 is also supported

- Basis for an accredited measurement laboratory according to DIN EN ISO/IEC 17025

- Transparent documentation and archiving of all process relevant data

- Automatic monitoring of test medium in laboratory

- Display of the customer and reference weight calibration history

- Incorporation of existing customer and calibration data into ScalesNet-M database

- Individual software module adaption

- Connecting of comparators and climate measurement station from any manufacturer

- Flawless, time saving and automatic creation of multilingual, linguistically accurate calibration certificates

- Verifiable software

- Individual service package

Most Important Features

- Central UNICODE SQL database to store all measurement data and other information

- Automatic input of weighting data via RS232 or TCP/IP ports. Port parameters can be generated depending on vendor information

- Automatic collection of room environment data during weighting cycles

- Number of weighting cycles and weighting type (ABBA, ABA etc.) selectable by classes

- Selection of Classes in accordance with OIML R111, ASTM 617 or other national standards

- Concurrent testing of weights from one set using multiple comparators in the laboratory

- Plausibility testing while selecting the standard set and a comparator to ensure that both are compatible with a chosen class

- All certified weights receive a test report, containing all data collected during the certification process (standard weight, used comparator, temperature, humidity, air pressure , etc.)

- Provides a complete history for any tested weight

- Freely customizable Test-, Calibration- or DKD-Certificates by the way of Word-Templates. Data and Test results are positioned in the Word Template via bookmarks (AsFound and AsLeft tables also avialabale). During the print process, the bookmarks are substituted with Test Results and Data

- All Certificates can be generated and printed in 2 languages

- Connection of a label printer is possible (for example Brother PT-2700)

- Results can be rounded conforming to OIML or GLP9

- Automatic generation of inventory lists of all used comparators and standard weights

- Monitoring Calibration Schedules of used comparators, standard weight sets and Climate Stations

The following modules are available

- ScalesNet-M Base Module, consisting of ScalesServer, ScalesDesk, ScalesMass, ScalesPrinter, Network Modules, a Module for all OIML classes F, all OIML classes M and all corresponding ASTM classes, Module to support up to 5 manual comparators, Climate Station Module

- Module ScalesMass, an Extension allowing concurrent calibration with one additional user

- Module ScalesDesk, allows administration of the data base (establishment and administration of customer data, comparators, standards, construction formulas, associates, access authorizations, etc.)

- Module ScalesPrinter, extends the basic version with the possibility to print to an additional printer

- Module Dissemination, extends the basic version to include mass derivation

- Module Robot, extends the basic version to connect robots manufactured by Sartorius and/or Mettler-Toledo

- Module automatic Weight Exchanger, extends the basic version to connect weight exchanger by Sartorius, Mettler Toledo and Radwag

- Module manual Comparators, extension to add 5 additional manual comparators

- Module for OIML Class E and respective ASTM Classes

- Module Climate Station, to extend the basic version with a Climate Station

Ethernet Connection

To use ScalesNet in a network, the basic version needs to be expanded by the module network.

ScalesNet can be only installed on a Windows platform!

Scales Server

This module administers the database and organizes all tasks; records the transactions carried out between database and user; establishes the connection to the climate stations and provides climate data when a request from the ScalesMass module is received, and polls climate stations for parameters in the mass metrology laboratory at user-defined intervals. In addition, climate parameters are polled during a weighing procedure and allocated to the corresponding weighing data. Data are transferred over an Ethernet connection to the database server.

ScalesDesk

Module for the administration of all base data, work orders, and printouts. The connection to the ScalesNet database server is implemented over Ethernet.

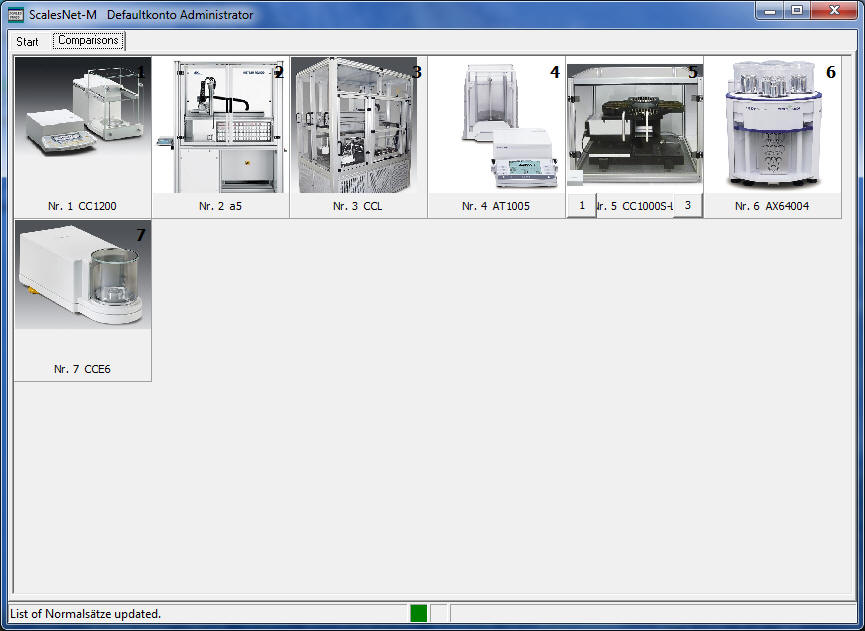

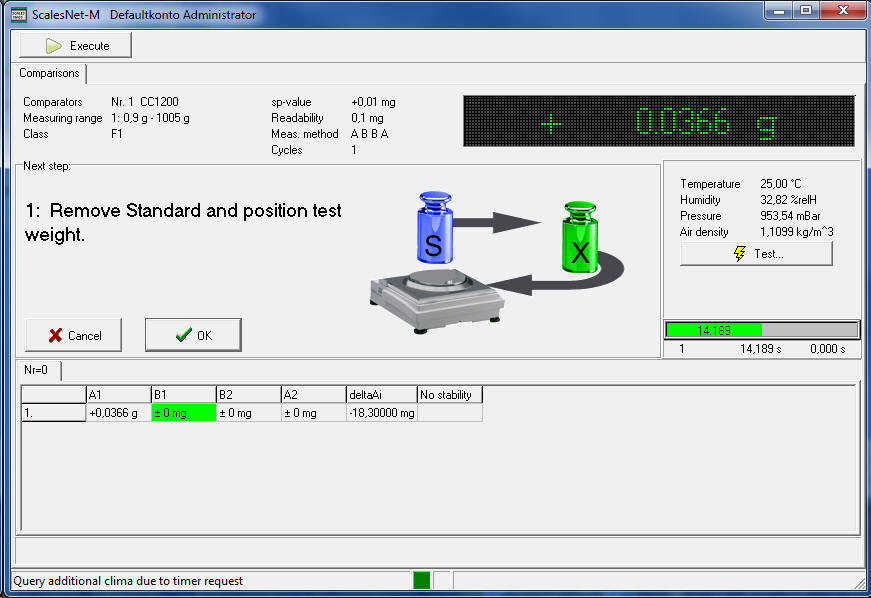

ScalesMass

This module handles the data concerning test piece and reference weight calibration and calibration/adjustment of mass comparators. The connection to the ScalesNet database server is implemented over Ethernet or WLAN.

ScalesPrinter

Organizes the printer spooler and print jobs, to ensure that each print job is sent to the selected network printer.

Software Requirements

- Microsoft Windows

- Microsoft Word

- Firebird Database (included in the delivery scope)

Hardware Requirements

- Laboratory PC with Server function, Windows 7, Windows 10, WinServer 2012 or higher

optimized for Windows applications, (CPU min i7, 16GB RAM

ScalesServer

ScalesCmd

ScalesPrinter + LabelPrinter

a) Firebird DB

b) Firebird DB located on host-system -

Laboratory PC Windows 7, Windows 10 optimized for Windows applications

ScalesDesk

-

Laptop optimized for Windows applications

ScalesDesk

ScalesMass

-

Rocket-Port (optional)

connection of all Climate Station -

Terminal Server Perle IOLAN or MOXA (optional)

All comparators

Climate station can be connected also

Several langauges available

English

German

French

Russian

Spanish

If another language is required, please contact support@maro.de

Databasemodel

- ScalesNet is based on the "thin client/fat server" model. This means as many processes as possible run directly on the server, rather than on the client machine. The database logic is represented on the server

- No data records are deleted. Each data record has a "Deleted" field. This field is set to 0 when active, and is set to 1 when the record is marked for deletion. As is the case with all changes in the database, the deleting of a record is noted in the log file

- Every time parameters in a data record are changed, a new record is created and the previous version of the record is marked for deletion. Simultaneously, an entry is record in the log file with references to the new and old data record

- The log file also contains the name of the table, type of access, date and time of access, user ID, etc

- When a report is created, the data record for that report contains the IDs to all data records required for generating the report. This means the report can be printed out at any time without having to save all the calculation results. Later modification of the data (for example, calibration of the weighing instrument is renewed) does not affect the record retroactively

Important

All installations for customers contain identical program codes. ScalesNet does not contain any customer specific program codes. Access rights to program sequences are controlled by programmable Hardlock.

Network Connection Diagram

The basic module of ScalesNet can be extended remotely to all available versions individually at any time, including Networking (LAN / WLAN), Automatic Comparators, Climate Stations, Dissemination (Mass Code), all Weight Classes of OIML and ASTM, as well as Robot Systems (Brand dependent).

Functions of ScalesMass

Calibration of Customer Weights (Test Pieces)

General Information

Calibration of test pieces is processed on the basis of a work order. This work order lists the job number, customer name or numbers, weight or weight set to be tested, type of test, mass comparator used, reference weight set and type of report. These data must be entered, or selected from the available data, before beginning the test. Supports also optional sensitivity weights and check weights. When robotic weighing instruments are used, a job can be defined for each magazine (weight platform for automatically loading weights onto the weighing instrument) encompassing n work orders, n serial numbers, the reference weight and the number of weights to be tested. This program sequence also includes the display of mass scales.

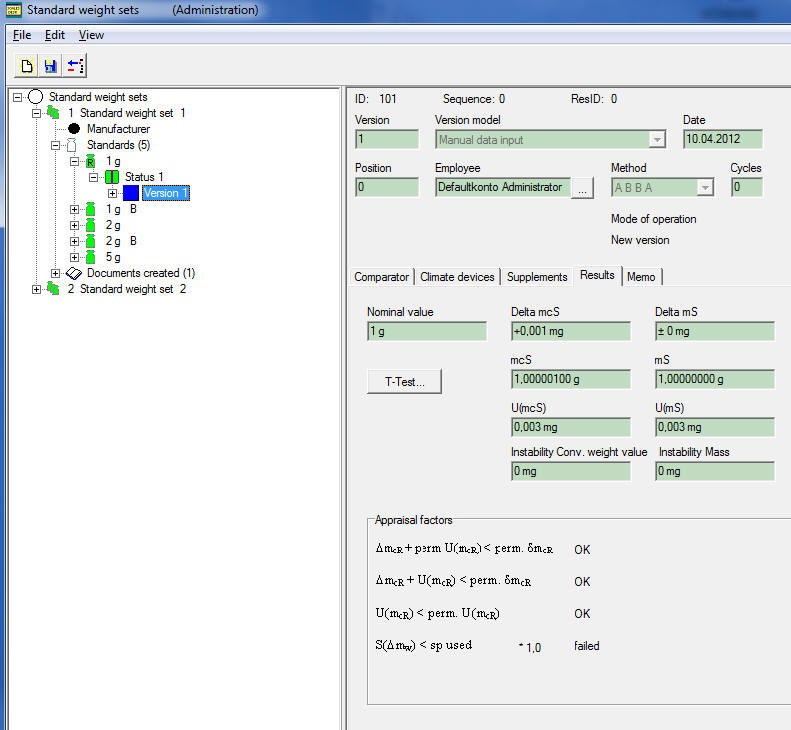

Calibration of Reference Weights

General Information

Data on references weights are entered in the base data for administration. In the calibration of reference weight sets, a distinction is made between external and internal calibration. All reference weight sets that require internal calibration are listed under Work order\Internal\Reference set, and can be calibrated internally in accordance with the specified guidelines. During internal calibration, the sequence is the same as for calibration of customer's weights, with the exception that no customer is selected. For reference weight sets requiring external calibration, data can be updated in the base data, with calibration date, calibration certificate number and calibration instance, by clicking on the "New calibration" button; the "Deviation" and Uncertainty" fields are cleared.

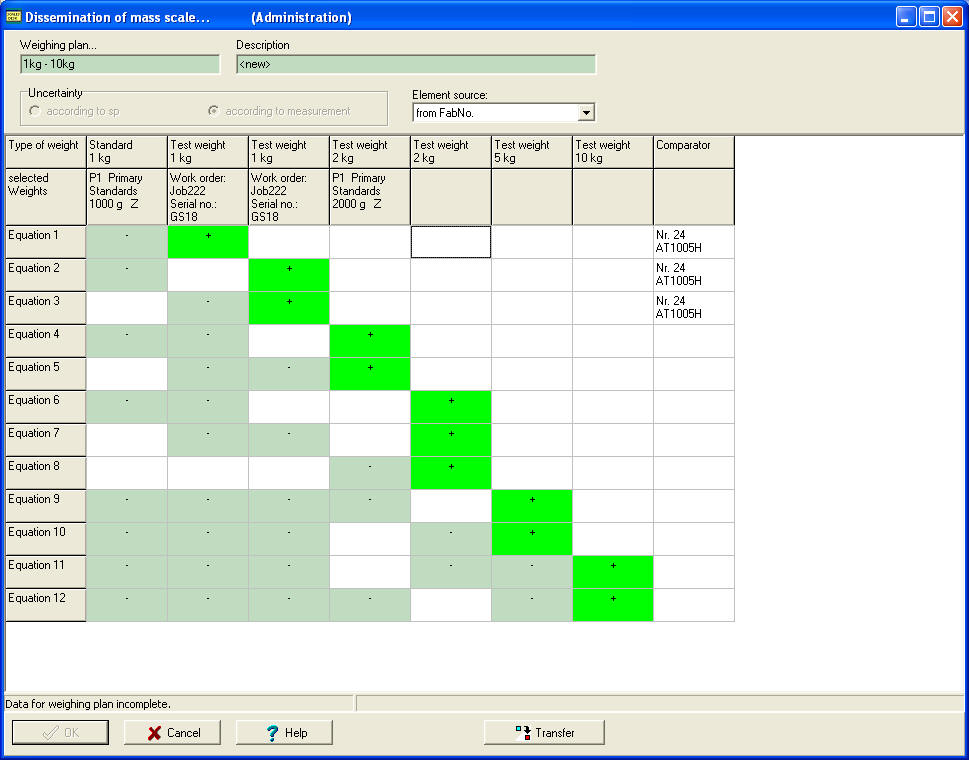

Dissemination of mass scale

General Information

Calibration of test pieces with Dissemination of mass scale is processed on the basis of a work order. This work order lists the job number, customer name or number, weight or weight set to be tested, type of test and type of report. The test pieces used in Dissemination of mass scale are not always from a single work order; for this reason, a job must be defined (similar to that described above for the robotic weighing instrument) that contains all work orders, customers and test pieces. Once this job has been defined, the weighing plan must be selected and the data pertaining to the weights (customer no., manufacturer, serial no., etc.) entered in the plan. The comparisons defined in the weighing plan form the basis of the comparative measurements to be performed on the weights. Result are in the entered matrices and calculated, and the values yielded are allocated to the individual weights. When robotic weighing instruments are used, multiple jobs can be defined for each magazine (weight platform for automatically loading weights onto the weighing instrument) encompassing n work orders, n serial numbers, multiple reference weights and the weights to be tested.

Quick Comparison of Weights

General Information

Select this menu item to perform a quick test. This feature lets you compare a test piece ether to a reference weight or to a manually entered value, for comparison without placing a reference weight on the weighing instrument. This test is not recorded in the database, but the data obtained can be exported for further processing with MS Excel.

Manual Input von Weighing Data

General Information

This module is for weighing instruments that do not have a data interface. The weighing instrument is defined in the base data and the operating mode "manual operation" is selected. Calibration of weights with this module is distinguished by manual input of weighing data. Subsequent calculations and printouts correspond to those described under "Calibration of Customer Weights (Test Pieces)."

Calibration of the Weighing Instrument

General Information

Calibration of the weighing instrument yields an sp value which can be used as the basis for calculating the permissible class. Calibration is performed at defined intervals. The intervals and a "grace period" are defined in the base data of the weighing instrument. When the calibration interval has elapsed, the weighing instrument is marked by a yellow symbol in the tree diagram, and the weighing instrument remains available for use during the grace period. If calibration is not performed before the grace period has elapsed, the instrument is marked by a red symbol and blocked from further use. When the ScalesMass program is run, a message window shows the weighing instruments for which the grace period is active or which are blocked from further use pending calibration.

Adjusting the Weighing Instrument

General Information

Adjustment of the weighing instrument is performed at defined intervals. The intervals and a "grace period" are defined in the base data of the weighing instrument. When the calibration interval has elapsed, the weighing instrument is marked by a yellow symbol in the tree diagram. If calibration is not performed before the grace period has elapsed, the instrument is marked by a red symbol and blocked from further use. The next time the program is run, a message window shows the weighing instruments for which the grace period is active or which are blocked from further use pending calibration. The distinction between internal and external calibration/adjustment affects the sequence of the procedure.

Functions of ScalesDesk

Database Administration of

- Customer

- Balances / Comparators / Load Changer / Robots / Prototyp-Balance

- Reference weights

- Employees

- Material of weights

- Manufaturere of weights

- Specifications OIMLR11, ASTM E617, NIST etc.

- Climate stations

- Shape of weights

- Open orders

- Reports, Protocols

Customer Data

The customer data base identifies customers by address and provides a Point of Contact (POC). An order can be placed and executed in connection with a customer only.

Data of Balances / Comparators / Robots / Change Loader / Prototyp-Comparator

The data base lists all scales and comparators available in the laboratory for use with ScalesNet.

Reference Weight

The data base provides all company generated norm data and weights respectively that can be used as references to test customer weights or to test internal norm sets.

Employees

All employees using ScalesNet must be registered in the data base by name and their password.

Material of weights

Data of the weight standards used are stored here. All relevant settings/given points for the defined standards (for example OIML R111, ASTM E617, NIST, etc ) are defined in this section.

Climate Stations

The data base lists all climate stations and the respective sensors necessary to collect all room parameters necessary.

Shape of the Weights

The data base contains the shapes of the weights.

Orders

The work orders are shown in a tree pictograph. All recorded and active orders are shown in the tree pictograph as

Preparing Reports and Records

Type of Report or Record

Reports and records are used for printing measurement data and header data. A distinction is made between internal and external reports or records.

Internal Records

Folgende Protokolle sind interne Dokumente:

- Test piece calibration record

- Protocol for results of Dissemination

- Inventory list for the weighing instrument

- Inventory list for the reference weights

- Inventory list for the climate stations

- Record of results from weighing instrument calibration

These records are made available in the form of MS Word templates, with bookmarks representing measured values or texts. These bookmarks are replaced by the corresponding value or text when the record is printed.

External Records

The external records are Word templates generated by the user. The required bookmarks are presented in a list for selection by the user; users can also add bookmarks for user-defined text passages. All bookmarks that represent text passages can be generated bilingually in this report. The language setting is saved along with the report (Word template). This makes it possible to create DKD calibration certificates in a variety of language combinations (e.g., German / English, Italian / English, etc.). Because the report uses a Word template, graphics can be inserted as well; for example, to add a logo, signature, stamp, etc. Bookmarks for out of tolerance, adjusted and replaced weights (as found and as left) are available.

- Example of Certificate: Example.pdf

- Position of Bookmarks: Bookmark_Position.pdf

- Name of used Bookmarks: Name_bookmarks.pdf

- Certificate printed: Certificate_completed.pdf

Trial Version of ScalesNet

For learning about ScalesNet-M we offer the following incentives:

- No-Cost*, three month unrestricted Trial version

- No-Cost Support via TeamViewer for the three month Trial periode.

* One week Installation and Training will be charged at our costs up front.

Demo-Sequences

open with mouse click.